The Versatility of Plastics Rotomolding: Applications and Advantages

Plastics happen to be a fundamental element of our everyday routine for decades now. We use plastic-type products for a variety of uses, whether it is for packing, storing, or attractive reasons. When the creation of plastic goods has evolved through the years, probably the most Rotational Molding exciting strategies for producing plastic-type goods is Rotomolding. Rotomolding is definitely an art work that involves the warming and molding of plastics to create a variety of merchandise. In this article, we are going to plunge strong into the field of Rotomolding and go over the different elements of the method.

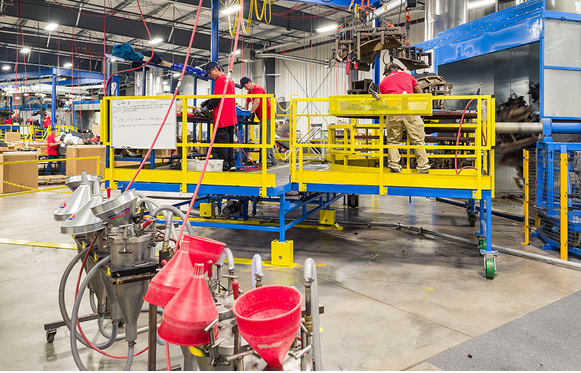

The 1st point along the way of Rotomolding entails the roll-out of a mold or resource. The mold is generally made of lightweight aluminum, metal, or epoxy and is also developed in line with the required features in the product or service. Once the mold is produced, it can be linked to a turning arm in the machine known as a rotomolding oven. The uncooked plastic material materials will then be included in the fungus either in powder or water develop.

The 2nd stage consists of heating the mold and the plastic-type from the cooker. The heat during this period can vary dependant upon the dimensions of the mold and the particular plastic material employed. Generally, the temp within the oven varieties from 250 to 400 diplomas Fahrenheit. Heating system the mold and plastic material to the temperatures brings about the plastic-type material to burn and follow the mold.

The third point consists of rotation of your fungus to be sure the plastic-type is uniformly handed out. The rotation from the stove is normally accomplished with a speed of 4 to 20 revolutions per minute. This procedure makes sure that the plastic material is equally handed out through the mold and that there are no oxygen wallets.

The fourth point involves cooling down the mildew along with the plastic. The mold is taken away from your cooker once the plastic-type material has solidified and cooled. The cooling process can even be accomplished manually by utilizing oxygen and drinking water. Once the plastic has cooled, this product is able to be pulled from the mold. The air conditioning process is crucial as it aids to ensure the plastic-type material does not warp or deform.

The ultimate stage entails cutting the extra plastic-type from your product. The item will then be inspected for almost any disorders or defects. As soon as the item goes by the evaluation, it is able to be packed and shipped to its ultimate location.

In short:

Rotomolding is actually a interesting process that generates plastic-type goods of diverse shapes and sizes. With this procedure, you can find no boundaries to the type of products which can be produced. The process is inexpensive and makes certain producing higher-quality products. If you are looking to make a plastic material item, Rotomolding is undoubtedly an alternative you should look at.